The cost effective advantage laminating system adheres a surprising variety of sheet or roll stock laminates using high performance hot melt film adhesive it feeds a substrate and our eco friendly hot melt adhesive film under infrared heat.

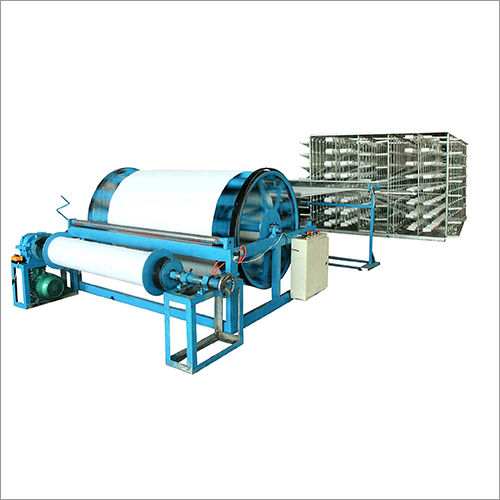

Hmt laminating machine.

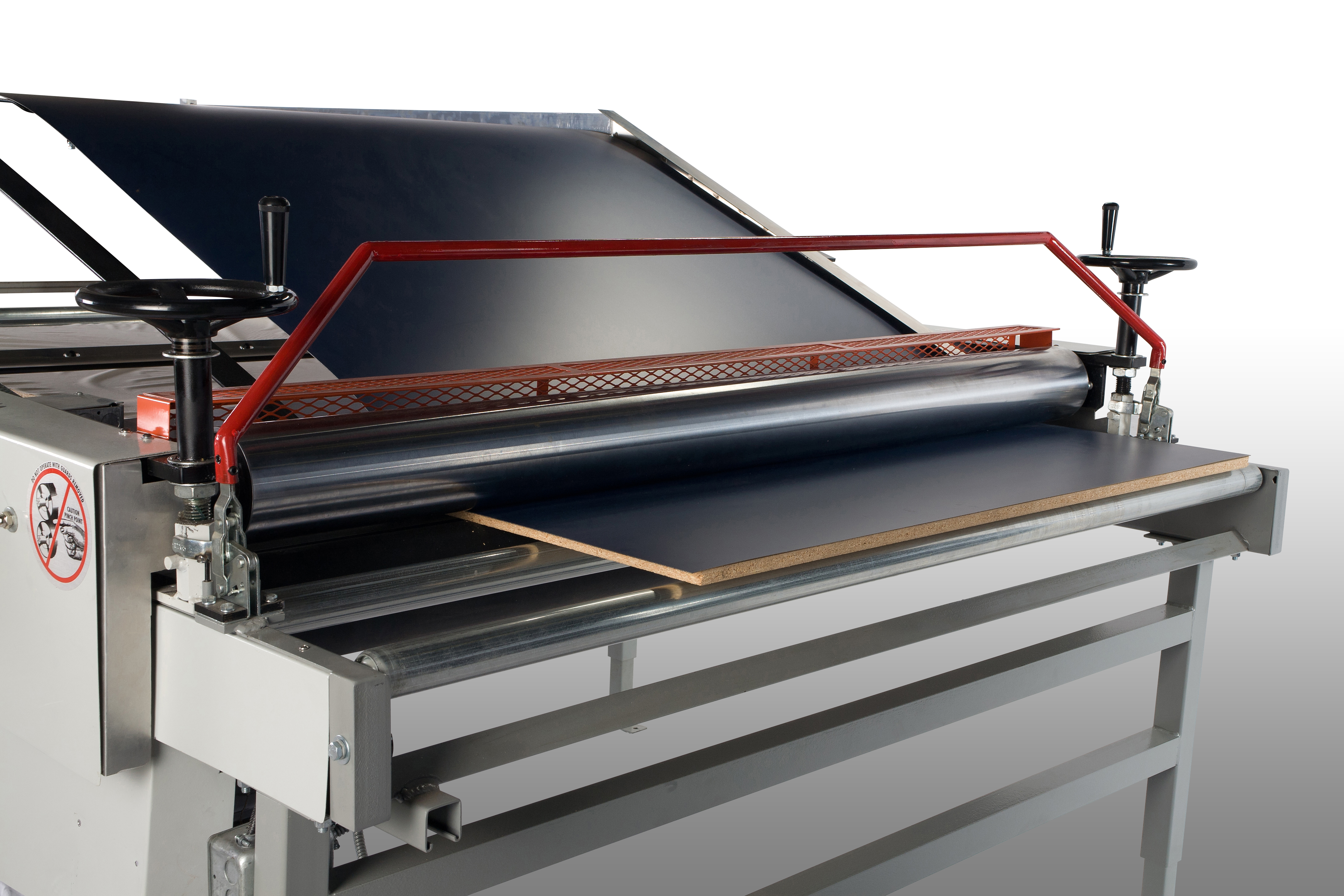

We use the hmt to laminate veneers and hpl to ply and pbd.

Its pretty cheaply made.

4 roller table extensions.

Hmt also builds custom laminating machines of various sizes upon request.

Works well can be tested if requested.

Hmt s smallest advantage laminator is 6 x10.

The low cost advantage can adhere many different substrates with numerous laminates in minutes allowing immediate fabrication.

With the roll feed option th.

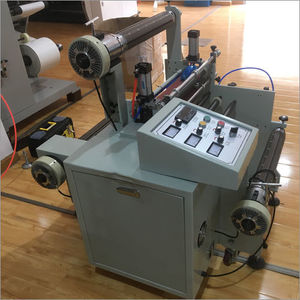

About 7 of these are laminating machines 0 are post press equipment and 1 are paper processing machinery.

Therm o web machinery division.

We did some major overhauling right from the factory.

Laminate is then joined using compression rolls for a finished.

10 500 208v 11 000 230v.

About 14 of these are laminating machines 0 are plastic extruders and 15 are coating machines.

That means the entire laminating process can occur in 60 square feet plus an area for panel output which varies depending on the material you produce.

Realistically a 2 man operation.

Other manufacturer advantage plus listed at 8 000 00.

No more waiting for glue to dry no more clean up no more uneven adhesive applications.

How to operate the advantage hmt hot melt adhesive film laminating machine duration.

Up to 61 output length.

An hmt advantage laminator uses about 1 3 the space of a spray booth.

Will be dissembled and loaded.

Better fence system more secure squaring rollers controls on both sides of machine.

A wide variety of supply hot laminating machine options are available to you such as driven type local service location and key selling points.